Can your gable fans generate the required negative pressure?

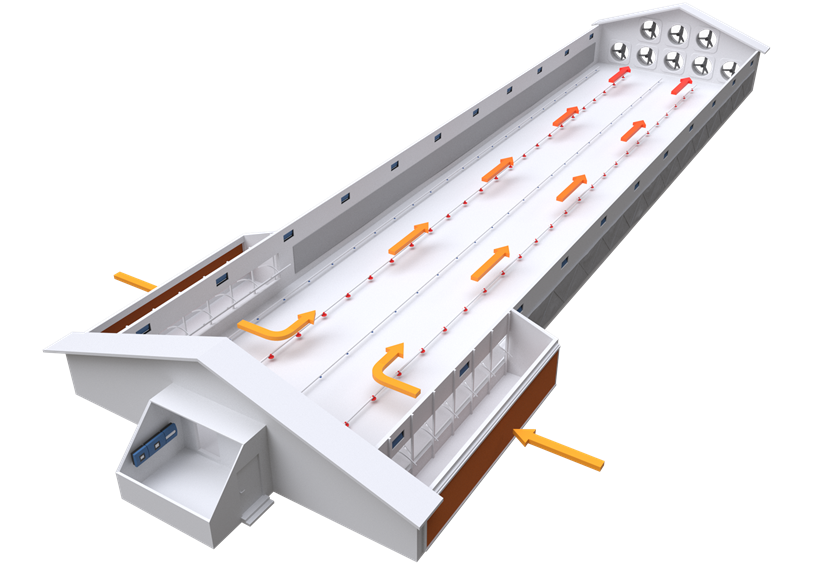

Tunnel ventilation is the most used system for ventilating poultry farms in hot climates. This is because it allows for cooling of the birds through pad cooling and air velocity.

Achieving the right climate with the appropriate air velocity is crucial to ensure batch uniformity, essential for high productivity and animal welfare. In Tunnel houses, there will always be a difference in the temperature between the front and the rear of the house, but some of the most influential factors are air velocity, leaks, and the building’s insulation.

If the actual temperature in the house is too high, the experienced temperature can be lowered with air velocity. The experienced temperature = actual temperature – (air velocity x chill factor). The speed of the air is what causes the chill, but it is essential that the air velocity feels like a light breeze for the chickens – not a draught – to experience the best spread and uniformity in the house.

The most critical factor for creating enough air velocity is ensuring that your gable fans can extract enough air and create the needed negative pressure.

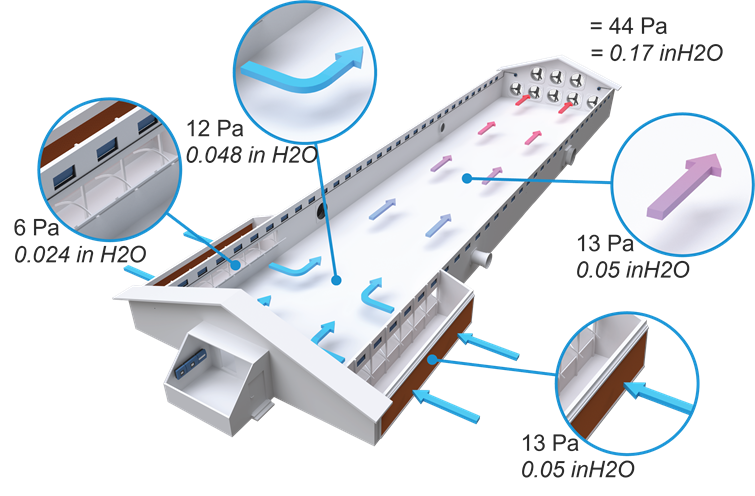

Several factors influence the pressure as the air moves through the house:

- Pads – The pressure drops as the air passes through the pads.

- Tunnel door – The pressure drops as the air enters through the door opening.

- Transitional – The pressure drops when the air needs to make a turn when entering the house.

- Longitudinal – The pressure drops gradually as the air moves through the house. The longer the house, the more pressure is dropped on the way.

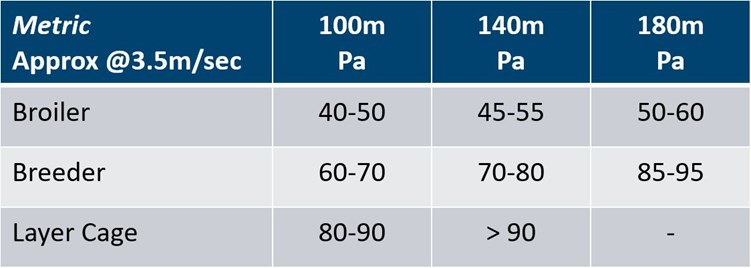

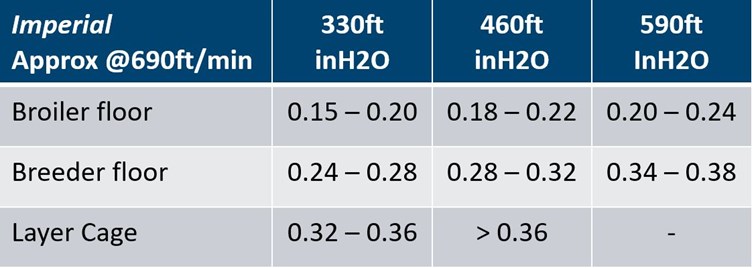

Obstacles vary between types of production and buildings but need to be considered when calculating the loss of pressure through the house:

- Bird type – Broiler, breeder, layer, etc.

- Type of production – Floor production, nest areas, cage production, etc.

- Livestock building – Purlins, pillars, lamps, feeding system, etc.

Example of pressure drop

The table shows a broiler house of 100 meters (328 ft) with floor production and no obstacles with a tunnel pressure for air velocity of 3.5 m/sec and 4.0 m/sec (688 ft/min and 790 ft/min).

Here, it is shown in a table - one with metric data and one with imperial data:

|

Metric |

3.5 m/sec |

4.0 m/sec |

|

Cooling pads |

13 Pa |

13 Pa |

|

Tunnel door (Rack&Pinion) |

6 Pa |

6 Pa |

|

Transition zone |

12 Pa |

16 Pa |

|

Front to rear |

13 Pa |

16 Pa |

|

Total |

44 Pa |

51 Pa |

|

Imperial |

688 ft/min |

790 ft/min |

|

Cooling pads |

0.05 inH2O |

0.05 inH2O |

|

Tunnel door |

0.024 inH2O |

0.024 inH2O |

|

Transition zone |

0.048 inH2O |

0.063 inH2O |

|

Front to rear |

0.052 inH2O |

0.063 inH2O |

|

Total |

0.174 inH2O |

0.2 inH2O |

As shown in the table, when increasing the air velocity from 3.5 m/sec to 4.0 m/sec, the needed pressure rises from 44 Pa to 51 Pa. The cooling pads and tunnel door continue to absorb the same amount of pressure, as they are dimensioned in size accordingly. In contrast, more pressure is dropped in the transition zone when turning because the increased air velocity causes more turbulence, which takes more pressure to turn the air direction. Additionally, the extra velocity causes higher resistance as the air travels from front to rear.

Consequently, if you want to increase the air velocity, for instance, from 3.5 m/sec to 4.0 m/sec, as in the above example, you need fans that can generate a higher negative pressure. Generally, higher air velocity causes higher resistance and, therefore, requires more pressure.

Choose the right fan for the job

Fans are designed for various purposes. Some are made to be energy-efficient, while others are made to be pressure-stable. Selecting the correct balance of energy efficiency and pressure stability is essential to maintaining the most suitable climate and animal welfare and achieving high productivity.

In many cases, selecting an energy-efficient fan is wise as it generates sufficient pressure and saves energy throughout its lifespan. However, there are situations where using energy-efficient fans would not be practical due to the high pressure requirement. This scenario may arise when the building is very long, has many obstructions, or the birds require high air velocity for cooling (m/sec).

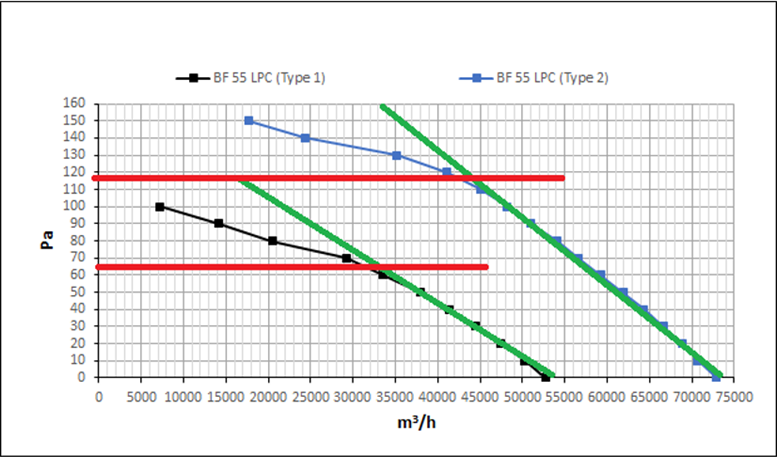

The graph displays the correlation between Pa and the amount of m3 air extracted per hour from a house, with the black line representing the energy-efficient BF 55 LPC fan and the blue line representing the pressure-stable BF 55 LPC fan. It could as well have been two other fans available on the market.

The green lines show when the pressure stability drops and the fans lower their performance. The red lines indicate where the fans start to suffer - the maximum pressure they can work with.

Example:

A breeder house of 140 meters (459 ft) with a needed air velocity of 3.5 m/sec (688 pies/min) requires 75 Pa (0.3 inH2O). It requires a system where the fans can exhaust 460,000 m3/h (270,800 CFM).

The BF 55 energy-efficient fan has an air capacity of 35,000 m3/h (20,600 CFM) per fan. 13 fans are needed to come close to the necessary amount of air exhausted per hour:

13 fans = 455,000 m3/h (267,800 CFM).

The BF 55 pressure-stable fan has an air capacity of 58,000 m3/h (34,150 CFM) per fan. It will take eight fans to reach the necessary amount of air exhausted per hour:

8 fans = 58,000 m3/h (273,200 CFM).

A guide for choosing the right fan:

Find test data on a large number of fans from various suppliers in the BESS Lab Report.