Power savings of

35-50% with BF 50

In May 2020, SKOV launched the BF 50 BlueFan that combines a minimum energy consumption with a high airflow ratio. Since 2020, we have done several tests around the world. This paper shows the findings of a test made in Australia from March 2020 to January 2021.

Traditional broiler farm with Combi-Tunnel ventilation

The test was carried out by the poultry producer Jacques Vorster and the manager of the farm Nico Theunissen who has a broiler production on a farm in the town of Donnybrook Kuikens, which is close to Brisbane. The broiler houses are ventilated by a Combi-Tunnel system, which SKOV installed approximately 13 years ago. The air outlet is handled by EM50 galvanized gable fans, supplemented with some smaller wall fans to ensure correct minimum ventilation. It is a conventional Combi-Tunnel setup, which SKOV has installed in many places around the world.

Test setup

In March 2020, SKOV Certified Service Partner FarmMark replaced all the traditional EM50 gable fans and side fans with BF 50 BlueFan to get comparable results in one house. The BF 50 BlueFan is a 50-inch box fan that can instantly replace the galvanized box fan one-to-one.

The building construction enabled the cone on the lower row of the BF 50, while it was not possible to install the cones on the upper row of the BF 50 fans due to lack of space. The BF 50 has a higher capacity than the EM50, so the number of fans could be reduced from sixteen EM50 to thirteen active BF 50 fans.

Since the BF 50 variant can be controlled steplessly from 0-100%, there was no need for the smaller EM36 and DA 600 wall exhaust to ensure correct minimum ventilation.

The feed, management, and genetics are 100% identical in the two houses!

Testing five batches

During the test period, the first batch of broilers was stocked in the two houses on March 2, 2020. After this, both houses became part of the regular production cycle on the farm.

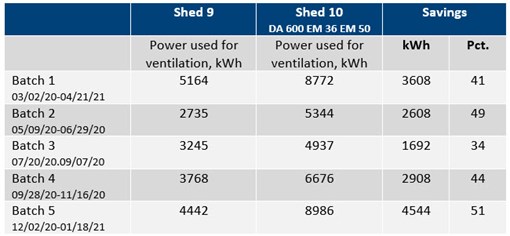

In total, we have registered the consumption of power in the two houses over five broiler batches, which make up most of a calendar year and thus have both cold and hot months. Batch number five was sent to the slaughterhouse on January 18, 2021.

Test result

As can be seen from the table, power savings were between 35-50%. The installation was a test installation, so we corrected the setup in connection with batch 2, 3, and 4.

The house with BF 50 BlueFan and Dynamic MultiStep controlled used, compared to the house with traditional EM50 fans and MultiStep controlled, approximately 15,400 kWh less in connection with the five batches.

If 1 kWh costs 0.31 AUD, it is equal to a saving of approx. 4,700 AUD for the five batches. When converted, it is approx. EUR 3,050 or USD 3,700.

The annual reduction of power consumption is higher than this, as the test period does not cover an entire year, just as it was a test run, where the installation with BF 50 was not set optimally throughout the test run.

The saving should be seen in relation to the additional investment. Depending on the variant, the price of BF 50 is higher than the EM50. On the other hand, fewer BF50 units are required, just as the installation is more straightforward by not installing EM36 and DA 600 for minimum ventilation.

Our experience shows that the additional investment is traditionally repaid in 2-4 years, depending on the climatic conditions, electricity prices, production form, etc.

The production results (FCR, mortality, etc.) were similar in the two houses.

Other BF 50 BlueFan benefits

In contrast to traditional box fans, the BF 50 is made of thermoplastic and stainless steel – non-corrosive materials that, by far, better withstand the harsh environment in a modern livestock house.

Traditional box fans are made of galvanized metal that requires replacements at regular intervals as they are exposed to the harsh environment of the livestock house.

The BF 50 with air-controlled shutters provides a higher degree of insulation compared to traditional box fans. The shutter is more airtight, and the box is better insulated.

The motor-controlled versions ensure that the position of the shutter, even at a strong wind, remains in its correct position. It also enables the use of an emergency opening. The shutter closes tightly, protecting against condensation and false air intake when the fan is not in operation.

Read more about BF 50 BlueFan here.